Electroplating Grade Zinc Sulfate Heptahydrate

Technical indicators

|

Item |

Standard |

||||||

|

First grade |

Second grade |

||||||

|

A |

B |

C |

A |

B |

C |

||

|

Main purity |

Zn w/% |

35.70 |

35.34 |

34.61 |

22.51 |

22.06 |

20.92 |

|

ZnSO4·H2O w/% |

98.0 |

97.0 |

95.0 |

|

|

|

|

|

ZnSO4·7H2O w/% |

|

|

|

99.0 |

97.0 |

92.0 |

|

|

Insoluble |

0.020 |

0.050 |

0.1 |

0.02 |

0.05 |

0.10 |

|

|

pH (50 g/L) |

4.0 |

4.0 |

|

3.0 |

3.0 |

|

|

|

Cl w/% |

0.20 |

0.6 |

|

0.2 |

0.6 |

|

|

|

Pb w/% |

0.001 |

0.005 |

0.01 |

0.001 |

0.005 |

0.01 |

|

|

Fe w/% |

0.005 |

0.01 |

0.05 |

0.002 |

0.01 |

0.05 |

|

|

Mn w/% |

0.01 |

0.03 |

0.05 |

0.005 |

0.05 |

|

|

|

Cd w/% |

0.001 |

0.005 |

0.01 |

0.001 |

0.005 |

0.01 |

|

|

Cr w/% |

0.0005 |

|

|

0.0005 |

|

||

Product use

It has applications in electroplating and electrolysis industries, and can also be used to make cables.

Zinc sulfate heptahydrate is widely used in galvanizing solutions. During electroplating, the biggest advantage of zinc sulfate heptahydrate solution galvanizing is that the current efficiency is as high as 100% and the deposition rate is fast. This is unmatched by other galvanizing processes.

The traditional sulphate zinc plating process is only suitable for electroplating of pipes and wires with simple geometric shapes due to the lack of fine crystallization of the coating and poor dispersion ability and deep crossing ability. In the zinc sulfate electroplating process of zinc-iron alloy, except for the main salt zinc sulfate, the other ingredients are discarded. An appropriate amount of iron salt is added to the new process formula to make the original single metal coating form a zinc-iron alloy coating. The reorganization of the process not only carried forward the advantages of high current efficiency and fast deposition rate of the original process, but also greatly improved the dispersion ability and deep plating ability. In the past, complex parts could not be plated, but now simple and complex parts can be plated, and the protective performance It is 3 to 5 times higher than that of single metal.

Production practice has proved that the continuous electrogalvanization of wires and pipes with zinc sulfate bath will have finer, brighter and faster deposition rate than the original coating. Meet the requirement of coating thickness within 2~3min

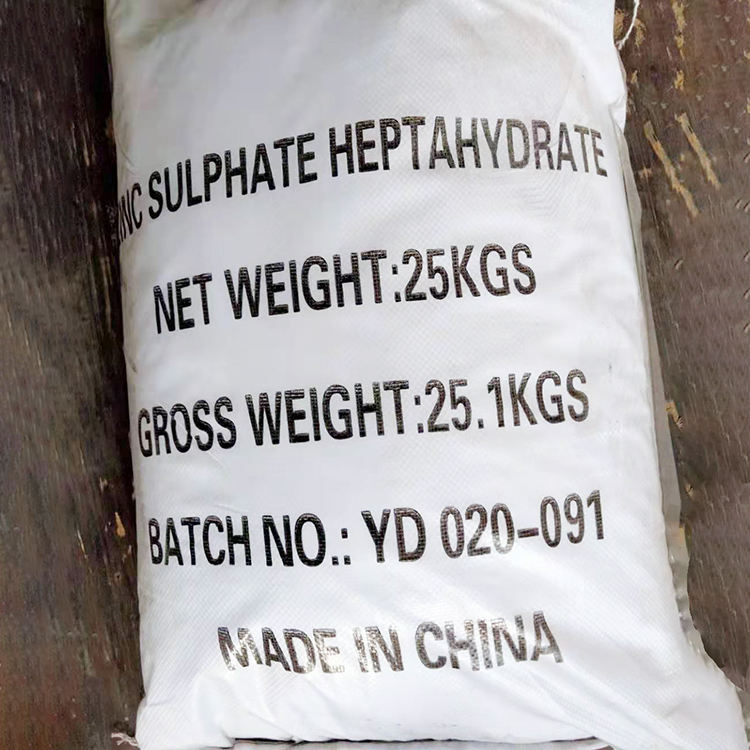

Product Packaging

( plastic lined, plastic woven bags)

*25kg/bag, 50kg/bag, 1000kg/bag

*1225kg/pallet

*18-25tons/20’FCL

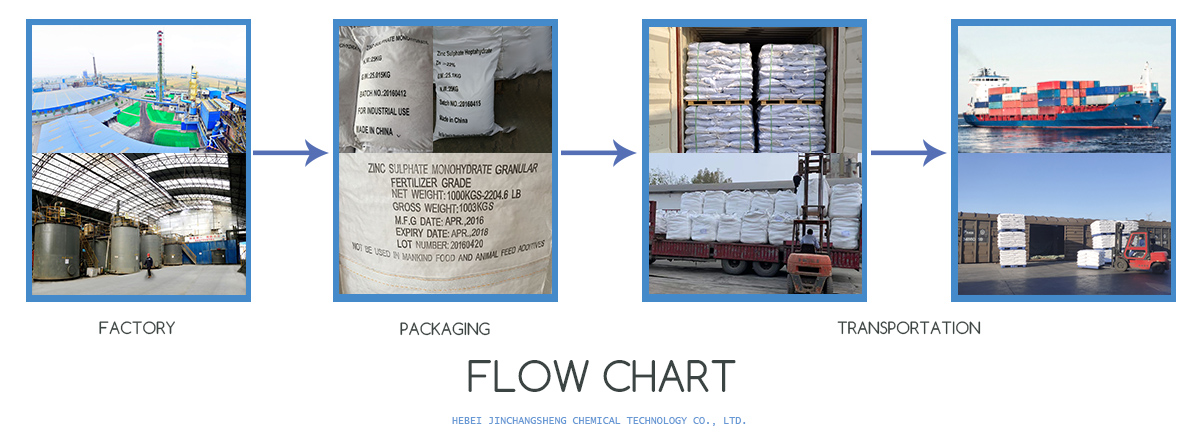

Flow chart

FAQS

1. Are you a trade company or factory?

We are a trade company and we have our own factory.

2. How do you control the quality?

We control our qualiy by the factory testing department. We also can do BV, SGS or any other Third-party testing.

3. How long time you will make shipment?

We can make the shipping within 7 day after confirm the order.

4. What documents you provide?

Usually, we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.

5.Which kind of payment terms do you accept?

L/C,T/T,Western Union.