Electroplating Grade Copper Sulfate

Technical indicators

|

Item |

Index |

|

CuSO4·5H2O w/% ≥ |

98.0 |

|

As w/% ≤ |

0.0005 |

|

Pb w/% ≤ |

0.001 |

|

Ca w/% ≤ |

0.0005 |

|

Fe w/% ≤ |

0.002 |

|

Co w/% ≤ |

0.0005 |

|

Ni w% ≤ |

0.0005 |

|

Zn w% ≤ |

0.001 |

|

Cl w% ≤ |

0.002 |

|

Water insoluble matter % ≤ |

0.005 |

|

pH value (5%, 20 ℃) |

3.5~4.5 |

Product Description

According to the production conditions and different requirements, the content specification of copper sulfate is 200~250g/L, 210~230g/L, or 180~220g/L. If the copper sulfate content is low, the allowable working current density is low and the cathode current efficiency is low.

The increase of copper sulfate content is limited by its solubility, and with the increase of sulfuric acid content in electroplating, the solubility of copper sulfate decreases correspondingly. Therefore, the content of copper sulfate must be lower than its solubility to prevent its precipitation.

Copper plating solution configuration method

First dissolve the calculated amount of copper sulfate in 2/3 of the configured volume of warm water, when the copper sulfate is completely dissolved and cooled, slowly add sulfuric acid under constant stirring (adding sulfuric acid is an exothermic reaction), static plating solution and filter , After adding the specified additives, the trial plating is qualified and it can be put into production.

Product Use Description

The application of copper sulfate as a solution in electroplating can effectively prevent the occurrence of pinholes, sand, blackening, mold and other faults in copper plating, and ensure the uniformity of the thickness distribution of the plate during electroplating and the deep plating ability for deep holes and small holes , And assist in improving the electrical conductivity, ductility and tensile strength of the coating.

Advantages of copper sulfate electroplating

(1) Copper sulfate plating provides gloss from high current density area to constant current density flow area.

(2) Copper sulfate coating has rich ductility and excellent leveling effect, which is widely used as the basis of decorative coating.

(3) The current efficiency of copper sulfate electroplating is almost 100%, and it can be electroplated with high current density

(4) Electroplating bath management and drainage treatment are easy.

(5) The internal stress of the copper sulfate coating is small and the coating is soft.

(5) The conductivity of copper sulfate plating is excellent.

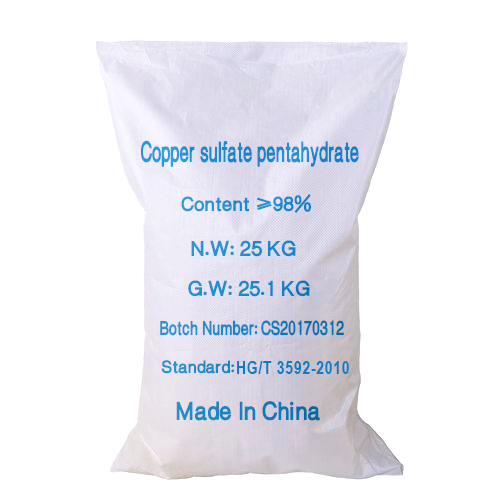

Product Packaging

1.Packed in plastic-lined woven bags of 25kg/50kg net each, 25MT per 20FCL.

2.Packed in plastic-lined woven jumbo bags of 1250kg net each, 25MT per 20FCL.

Flow chart

FAQS

1. Are you a trade company or factory?

We are a trade company and we have our own factory.

2. How do you control the quality?

We control our qualiy by the factory testing department. We also can do BV, SGS or any other Third-party testing.

3. How long time you will make shipment?

We can make the shipping within 7 day after confirm the order.

4. What documents you provide?

Usually, we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.

5.What is your acceptable payment term?

L/C,T/T,Western Union.